Optical Components & Transceivers

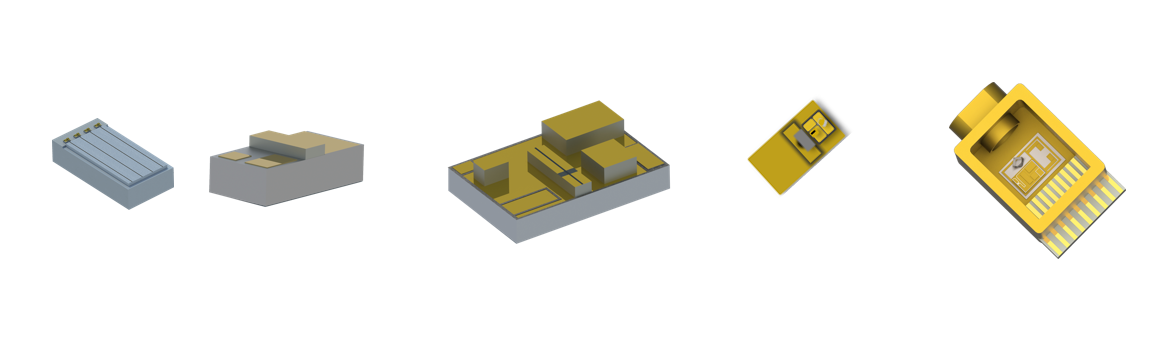

For Optical Transceivers, the Chip-on-carrier/submount (CoC/CoS) bonding is done first. Then the CoC/CoS is bonded onto a common baseplate for lens/mirror attachment before putting it into a package. The latest trend is for more components such as the lasers, capacitors, and thermistors to be attached onto a common carrier by either eutectic or epoxy die bonding. For gold-box packaging such as transceivers with high-power lasers, typically chip-on-carrier/submount (CoC/CoS) bonding is done first and then the CoC/CoS is bonded onto a common baseplate for lens/mirror attachment before putting it into a package. More chips or die need to be attached onto a common carrier by either eutectic die bonding or epoxy die bonding.

Die Attach

-

Eutectic

-

Epoxy stamping

-

0.5μm, 1.5μm, 3μm, 5μm

-

Chip-on-Carrier (CoC), Chip-on-Submount (CoS)

Lens Attach

-

UV epoxy dispensing

-

In-situ UV curing

-

Placement accuracy options: 3μm, 5μm

-

Passive Optical Alignment

Gold-box Packaging

-

Thermal and UV Epoxy

-

Eutectic

-

Placement accuracy options: 3μm, 5μm