MY300LX pick-and-place

MY300LX pick-and-place

- All-in-one All-in-one mounter, up to 16,000 CPH

- High accuracy High accuracy and repeatability for fine pitch placement

- Agilis feeder technology Agilis feeder technology featuring up to 192 feeder positions

Master complexity. Grow your business.

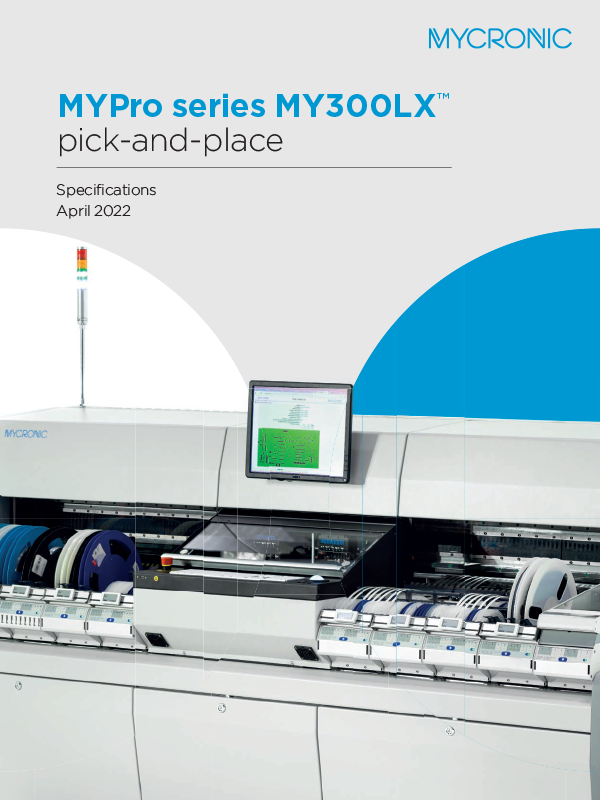

Populate more boards. Not more floor space.

Get more jobs done in less space with Mycronic's pick-and-place machines. Thanks to the machines’ compact design, up to 224 intelligent feeders can be accommodated within a surprisingly small footprint.

Switch effortlessly from full volume to batch size one. Handle a wider range of components with uncompromising production quality, total stock accuracy and complete traceability down to individual PCB serial number.

The MY300 delivers SMT pick-and-place at next level precision and flexibility in a fast, small and smart format.

Key benefits:

- Up to 192 feeder positions

- Top speed of 16,000 CPH

- Full component range in one machine

- Fastest set-ups and changeovers in the industry

- Capable of pin-in-paste, PoP, QFN, board cavities and more

- On-the-spot board revisions

- Handle short tape strips and non-standard carriers

- Electrical verification of resistors, capacitors, diodes and transistors (optional)

Agilis™ - The most efficient feeding system

Mycronic’s modular Agilis™ component feeding system is designed for accuracy, ease of use and convenience. It gains unrivalled flexibility from a combination of intelligent feeders and magazines for tapes and sticks.

Our unique Agilis™ feeders with no moving parts are easier and quicker to load than any other on the market. And by keeping preloaded Agilis feeders on hand, you can perform set-ups and changeovers even faster.

Since all Mycronic magazines can be replenished while the machine is running, you never have to stop production if you run out of components.

Contact

Learn from Mycronic's experts

Sign up here to get updates on upcoming events, latest industry information and product news within Mycronic PCB Assembly solutions.